A guide to drilling

The right cordless drill for every application

The torque setting and selection of the right speed are the two most important factors for achieving a perfect drilling result, since they precisely adjust the drill process to the screw properties, its diameter and, most importantly, the material.

Cordless impact drivers are taking tradespeople by storm

Several speeds for greater variety

The range of applications that are possible with the QUADRIVE TPC 18/4 cordless percussion drill with four-speed gearbox is extremely versatile. The four-speed powerhouse is ideal for drilling tasks involving high torques, large diameters, and quick and powerful drilling. As a rule of thumb, the larger the drilling diameter, the lower the speed. Festool has developed a clever solution for switching between speeds, with both tools allowing users to switch from one gear straight to another. When changing gear controls, each gear shifts into place for guaranteed safety and full control while drilling.

KickbackStop protects the wrist

Festool Cordless Drills

Many tradespeople often use maximum torque for drilling. With the T 18+3 and C 18 cordless drills, you can switch from maximum torque to a lower torque setting by pressing a button. "Our cordless drills feature fully electronic torque settings and shut-off. This is particularly useful for drilling, since it allows for a very precise adjustment of force and speed. And that is exactly what many tradespeople value, as they prefer drilling with high precision," explains master carpenter von dem Bussche and adds: "If screws are overtightened or screw heads are even shorn off, this is usually due to mistakenly using maximum torque for drilling. This damages both the screw and drill bit."

Extra-small cordless drills

Compact cordless drills are particularly recommended for assembling carcasses, ceiling linings, and wall cladding. The very short design, balanced weight distribution and low weight of just 900 g makes it easier to work overhead or in hard-to-reach areas. The TXS 18 (T-shape), CXS 12, and CXS 18 (C-shape) cordless drills have been demonstrating their suitability for assembly tasks for more than a decade. The powerful motor is supplied with power by a 12 V or 18 V lithium-ion battery pack. There are twelve torque settings for controlled power. Festool has also designed its TXS and CXS models for extremely precise work.

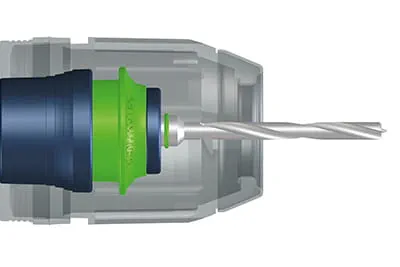

Quick-change system for bits, drills and tool chucks

Special attachments for efficient work